Ceramic armor plates serve as protective shields in modern defense. Engineers design ceramic armor using advanced materials that block bullets and shrapnel while keeping the weight low.

Many military body armor systems rely on ceramic armor plates, combining hard ceramic with strong fabrics to protect users. These plates play a vital role in defense.

- Infantry units use ceramic armor plates for protection from small-caliber fire and shrapnel.

- Vehicle crews benefit from lightweight shielding inside armored vehicles.

- Special operations teams depend on ceramic armor for defense against armor-piercing rounds.

- Law enforcement units rely on these plates for mobility and protection during tactical missions.

Manufacturing Process of Ceramic Armor Plates

The journey from raw materials to finished ceramic armor plates involves several precise steps. Manufacturers focus on accuracy and consistency to ensure each plate meets strict standards for ballistic performance. The process includes powder preparation, forming, sintering, hot pressing, and quality control.

Powder Preparation & Forming

Engineers begin by preparing ceramic powders. They select high-purity raw materials and remove impurities to improve the final product. The process follows a series of steps:

- Milling separates unwanted particles and improves the mixability of the powders.

- Sizing, batching, and mixing refine the powders and create a uniform compound.

- Forming shapes the mixed powders into plates using methods such as slip casting or injection molding.

- Glazing adds a protective layer to enhance the surface and durability.

- Firing heats the glazed plates to achieve the required density and hardness.

The particle size distribution of ceramic powders plays a critical role in the properties of ceramic plates. The table below shows how particle size affects the final product:

| Influence | Description |

|---|---|

| Densification | Smaller particles enhance densification during sintering, improving mechanical properties and durability. |

| Transport Properties | Affects flow and mixing behavior, ensuring uniformity in material properties for consistent performance. |

| Mechanical Strength | Uniform particle sizes lead to consistent strength, reducing the risk of fractures under load. |

| Thermal Stability | Smaller particles increase surface area, influencing thermal conductivity and heat resistance. |

Sintering & Hot Pressing

After forming, the ceramic plates undergo sintering and hot pressing. Sintering uses high temperatures to bond the particles and increase density. The process usually takes place at temperatures between 1700°C and 1850°C. Pressureless sintering can work, but hot pressing provides better results by distributing heat evenly.

Hot pressing improves the mechanical properties of ceramic armor plates. The plates become harder and more resistant to impact. Manufacturers monitor temperature and pressure closely to avoid defects and ensure consistent ballistic performance.

Engineering Principles Behind Ballistic Performance

Ceramic armor plates use advanced engineering to achieve high ballistic performance. These plates defeat projectiles by shattering, eroding, and absorbing energy. The combination of high-performance ceramics and composite design allows for effective ballistic resistance in defense applications.

When a projectile hits a ceramic plate, there is localized fracturing of the ceramic, causing the projectile to dump massive amounts of its energy. The ceramic breaks up the bullet, and then the fragments are caught with backing materials like Kevlar.

Backing Layer Absorbs Remaining Energy

The backing layer plays a critical role in ballistic armor systems. After the ceramic armor shatters and erodes the projectile, the backing layer absorbs the remaining impact energy and catches fragments. This process protects the wearer from spalling and bullet fragmentation.

- The backing layer absorbs residual energy from impacts, reducing the force transmitted to the wearer.

- It captures fragments created when the ceramic strike face fails, preventing them from becoming dangerous projectiles.

- This design feature is crucial for safety, as it mitigates the risk of spalling and bullet fragmentation.

Force Spreads Across the Strike Face

Ceramic armor distributes the force of ballistic impacts across the strike face. The hard ceramic layer shatters the incoming projectile, which helps to dissipate the energy. The backing material then absorbs the remaining energy, preventing further penetration and minimizing blunt force trauma.

| Observation | Description |

|---|---|

| Cracking | Transverse and radial cracks observed in the ceramic tile. |

| Layer Separation | Thin layers separation, bullet holes, and pits noted in the laminate. |

| Morphology | Kink, sheared, and torn morphology were present. |

| Bulge Shape | Transition from circular to rectangular shape in the bulge button face. |

| Shear Strain | L-shaped pattern in shear strain distribution. |

| Energy Conversion | About 8.73% of bullet kinetic energy converted into total bulge kinetic energy, with x- and y-directional kinetic energy accounting for 29.66%. |

Multi-Hit Performance

Ballistic performance depends on how well ceramic armor plates handle multiple impacts. Several factors influence multi-hit capability:

- Ceramic plates can handle multiple rounds if they do not hit the same spot.

- Cracking occurs upon impact, which reduces protective capabilities.

- Backing materials like Kevlar help maintain structural integrity after hits.

- Shot placement is crucial; concentrated hits can degrade armor quickly.

- Bullet velocity affects the armor’s ability to withstand multiple impacts; higher speeds cause more damage.

- Plate construction quality determines multi-hit capability against various threats.

- Proper fitment of the plate is essential for maximizing protection.

- The type of ammunition used can influence the effectiveness of the armor against multiple hits.

Ceramic armor plates provide reliable ballistic resistance by combining high-performance ceramics with strong backing layers. This engineering approach ensures that ballistic armor delivers consistent protection in defense scenarios, even under repeated ballistic impacts.

Integration & Standards in Ceramic Armor Plates

Combining Ceramics with Backing Layers

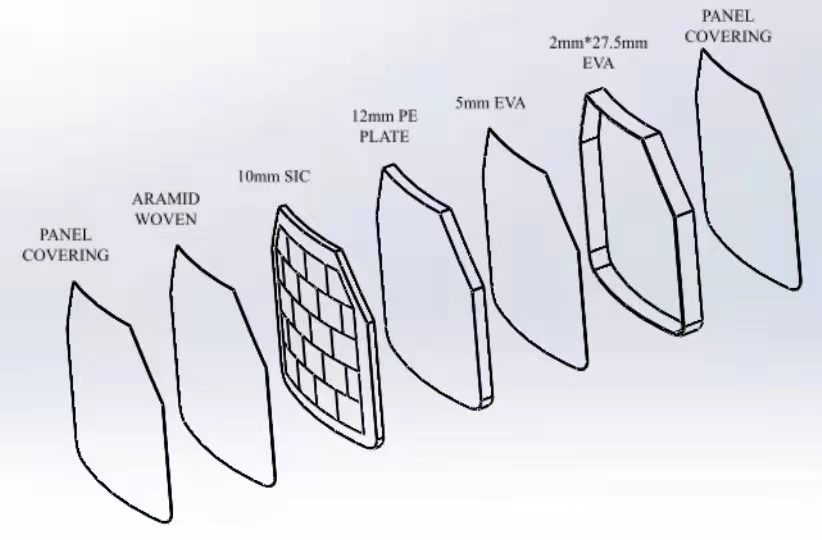

Ceramic armor plates work best when engineers combine them with strong backing layers. They often place ceramic panels inside soft ballistic vests. This integration creates a lightweight shield that protects users from bullets, knives, and shrapnel.

Designers select ceramics for their ability to fracture upon impact, which absorbs energy and disrupts high-velocity projectiles. The backing layer catches fragments and spreads force, improving survivability. Some ceramic armors withstand multiple impacts, which increases protection in dangerous situations.

- Ceramic plates fit into soft vests for added protection.

- The hard ceramic surface resists penetration and reduces weight.

- Backing layers absorb energy and catch fragments.

- Multi-hit designs help users stay safe during repeated threats.

Defense Standards & Testing

Manufacturers must test ceramic armor plates to meet strict defense standards. They use several methods to check ballistic resistance and durability. Engineers drop plates from controlled heights onto hard surfaces.

They assess impacts at different angles and repeat stress tests to simulate real-world use. After each test, they analyze the plate for cracks and structural damage.

- Drop plates from various heights to test impact resistance.

- Strike plates at different angles to check performance.

- Apply repeated stress to measure long-term durability.

- Inspect plates after impact for structural integrity.

Testing also includes exposing plates to extreme temperatures and rough terrain. These steps ensure that ceramic armor meets military requirements and performs well in harsh environments.

Durability & Cost Factors

Ceramic armor plates must last through tough conditions. Several factors affect their durability and cost. Material hardness determines how well the plate stops projectiles.

Energy dissipation helps convert impact into harmless material breakdown. Strong bonding between ceramic and backing layers keeps the plate intact after hits. Advanced manufacturing techniques create multilayered composites that adapt to different threats.

Ceramic armor costs more than traditional metal plates, but it offers better protection and lower weight. Comprehensive testing and high-quality materials ensure that ballistic armor remains reliable in defense operations.

Conclusion

Ceramic armor plates use advanced materials and precise manufacturing to protect military personnel. Recent innovations include new predictive formulas, improved silicon carbide and boron carbide systems, and advanced backing materials.

Mosaic designs and better adhesives increase multi-hit capability. Ceramic armor reduces serious injuries in combat and improves survivability. Future trends focus on hybrid solutions, smart materials, and 3D-printed designs for lighter, stronger protection.