Project Description

Custom High Quality Ballistic MICH Helmet from H WIN

The MICH helmet offers reliable head ballistic protection for military, law enforcement, and security personnel. Lightweight yet durable, this combat helmet is designed for comfort and compatibility with tactical accessories.

Key Features:

- Lightweight design: Minimizes strain during extended wear.

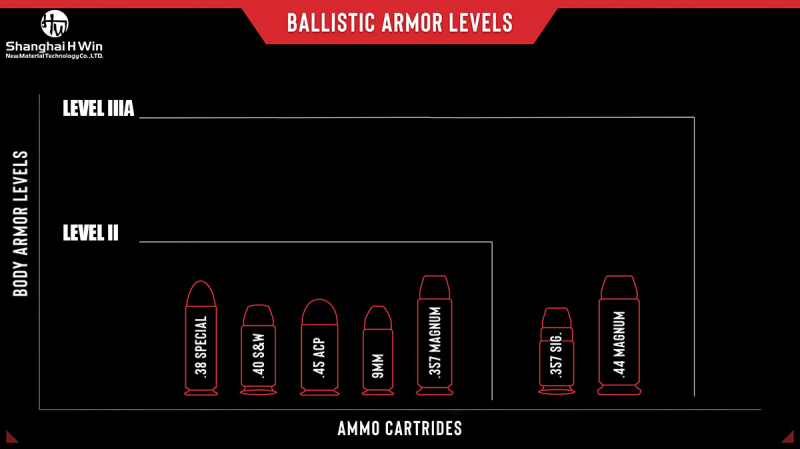

- NIJ IIIA protection: Certified ballistic resistance against handgun threats and fragments.

- Customizable fit: Adjustable system ensures a secure and comfortable feel.

- Accessory rails: Allows for integration of lights, communication devices, etc.

- High-cut design: Provides enhanced situational awareness.

H Win MICH Ballistic Helmets: Setting a New Standard

The H Win mich ballistic helmet represents a significant advancement in head protection technology. Crafted using premium materials like Polyethylene or Aramid, this special forces MICH helmet delivers exceptional ballistic performance without the weight penalty of older helmet designs.

MICH helmets with rails are designed to integrate seamlessly with essential tactical gear. This MICH helmet includes a customizable fit system, allowing for precise adjustments and optimal comfort during extended wear. The interior padding system also enhances comfort and stability.

MICH Ballistic Helmet Specifications

| Feature | Details |

|---|---|

| Model | HW-HMICH |

| Protection Level | NIJ IIIA |

| Sizes | M/L/XL |

| Thickness | 0.5″ |

| Weight | 3.3 lbs |

| Shell Material | Polyethylene or Aramid |

| Cover Material | Polyester |

| Warranty | 5 Year Manufacturer’s Warranty |

FAQ

1. What is the primary advantage of a MICH helmet?

The key advantage of a MICH helmet is its improved balance of protection, lightweight comfort, and compatibility with modern tactical gear.

2. Can I customize the H Win MICH Helmet with different colors or camouflage patterns?

Yes, customization options are available. Contact our sales team for details.

3. What’s the difference between a MICH helmet and a PASGT helmet?

The MICH (Modular Integrated Communications Helmet) is a more modern design than the PASGT (Personnel Armor System for Ground Troops) helmet, offering several key advantages:

- Profile: High-cut design for better field of vision and compatibility with comms gear (vs. PASGT’s lower profile).

- Weight: Generally lighter than the PASGT, reducing fatigue.

- Modularity: Integrated accessory rails for attaching lights, NVGs, etc. (vs. PASGT’s limited options).

- Impact Protection: Often features enhanced blunt impact protection.

4. Are MICH helmets still used?

While the MICH has been largely replaced by the ACH (Advanced Combat Helmet) in standard US military issue, MICH helmets are still used by some units and are popular with law enforcement and security forces worldwide. Their high-cut design and accessory rails offer advantages for tactical operations.

Related Ballistic Helmets

Request a free quote for H WIN’s MICH Helmet today!

We provide OEM service and ready to meet your requests.

What Is a MICH Helmet

A MICH helmet is defined by its shell geometry, coverage profile, and internal system architecture. These elements distinguish it clearly from PASGT helmets, FAST helmets, and other tactical helmet families.

Key defining characteristics include:

- A reduced and contoured shell profile

- Improved balance and stability on the head

- Compatibility with communication headsets

- A pad-based internal suspension system

- A four-point retention system

Shell Geometry and Coverage

Overall Shape

The MICH helmet shell has a lower profile than older PASGT helmets. The front, sides, and rear are contoured to sit closer to the head. This improves weight distribution and reduces movement during dynamic activity.

The rear of the shell is designed to maintain coverage while allowing better compatibility with body armor collars and load-bearing equipment.

Cut Variations

MICH helmets are produced in several cut configurations, all based on the same core geometry.

Full-Cut MICH Helmet

The full-cut version provides maximum side and ear coverage. It prioritizes surface protection and is often selected where headset use is limited or secondary.

High-Cut MICH Helmet

The high-cut version removes material around the ear area. This allows direct use of over-ear communication systems and active hearing protection. The reduction in coverage is a deliberate trade-off to improve functionality.

Both cuts remain MICH helmets because the underlying shell design and structural intent remain unchanged.

Shell Materials and Construction

Aramid Fiber Construction

Most MICH helmets are manufactured using aramid fiber composites. These materials provide reliable resistance to fragmentation and handgun threats while keeping weight within acceptable limits.

The shell is formed through layered fabric layup, resin impregnation, and controlled curing. Fiber orientation and layer count are critical factors that influence ballistic performance and backface deformation.

UHMWPE and Hybrid Structures

Some MICH helmets are produced using UHMWPE or hybrid aramid-PE constructions. These shells reduce overall weight and improve long-term wearing comfort.

Material choice affects heat tolerance, stiffness, and aging behavior. For this reason, material specification must always be clearly defined when discussing a MICH helmet.

Ballistic Performance Scope

Protection Level

A standard MICH helmet is designed for handgun and fragmentation protection. Performance is commonly aligned with NIJ Level IIIA expectations, although helmets are evaluated differently from armor plates.

Protection typically includes:

- Resistance to common handgun rounds

- Fragmentation protection based on V50 testing

- Control of blunt impact energy through padding

Backface Deformation

Backface deformation is a critical parameter for helmet performance. Even when penetration does not occur, excessive deformation can cause injury.

Shell stiffness, fiber selection, and internal padding all contribute to deformation control. The helmet must be evaluated as a complete system, not as a shell alone.

Internal Padding System

Impact Pads

Modern MICH helmets use modular foam padding instead of webbing suspension. These pads absorb impact energy and stabilize the helmet during movement.

Pad thickness, density, and layout directly affect comfort and impact performance. Poor pad quality can significantly reduce protection, even if the shell performs well in ballistic tests.

Adjustability

Pads are typically removable and repositionable. This allows the helmet to fit different head shapes while maintaining consistent shell positioning.

Retention System Design

Four-Point Chin Strap

The standard MICH helmet uses a four-point retention system. This design keeps the helmet stable during running, kneeling, and vehicle operations.

Strap geometry ensures even load distribution across the head. Buckle strength and strap material quality affect long-term reliability.

Stability Under Load

When accessories such as night vision devices are mounted, retention performance becomes more important. The MICH helmet design balances shell shape and strap placement to manage forward weight.

Accessory Integration

Front Mount Interface

MICH helmets are designed to accept a front mounting bracket for night vision devices. Mount positioning follows established dimensions to ensure compatibility.

The shell must maintain sufficient thickness and reinforcement in the mounting area to avoid stress cracking.

Side Accessory Support

High-cut MICH helmets allow side-mounted accessories such as communication headsets. Shell cut and rail placement must preserve structural integrity while enabling attachment.

Accessory integration is a functional requirement, not a decorative feature.

Functional Advantages of the MICH Helmet

- Predictable ballistic performance

- Stable fit and balance

- Effective communication compatibility

- Mature and repeatable manufacturing processes

Structural Limitations

- No rifle-level ballistic protection

- Reduced coverage in high-cut configurations

- Dependence on pad quality for impact protection

Manufacturing Control Points

Consistent MICH helmet production requires attention to:

- Fiber layup accuracy

- Resin content control

- Curing temperature stability

- Shell thickness uniformity

- Lot-based ballistic sampling

Deviation in any of these areas affects performance consistency.

.jpg)